|

Home --> Heritage

|

|

Heritage

|

A potted history of Gedling Colliery & Country Park

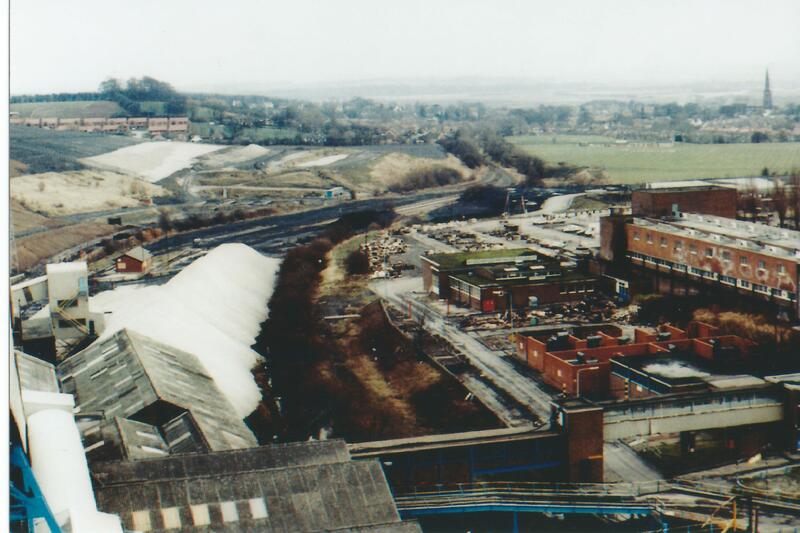

1895 – The site many people refer to locally as the “old pit” was, up until the end of the nineteenth century used for agriculture, with gentle rolling fields stretching up gradually to Spring Lane. 1899-1902 – The colliery was originally built and owned by the Digby Colliery Company which later merged to become Bestwood Amalgamated Collieries Ltd. 1902 – Gedling Colliery first started to produce coal. Originally two seams were worked - the Top Hard and the Main Bright. The High Hazels seam was first developed in 1927. 1902-1991 – The main period of operation for Gedling Colliery. Of the coal produced, 20% was steam coal and 80% was household lump coal. 1947 – The pit was nationalised and became known as the National Coal Board South Nottinghamshire Area from 1967. The current landscape of the park was created from the colliery waste. Once the colliery spoil was deposited, the 'slag heaps' were then covered with top soil. The current hills within the park are a result of 92 years’ worth of mining extracts. 1991 – The colliery was closed and the mine infrastructure de-constructed. The Winding Wheels and other materials were relocated. However, we've been fortunate to locate and store two of the original mine cars and these will be located at the Spring Lane entrance to the park. These will form part of a proposed heritage trail. Approx. 1998-2003 – When the UK coal industry was privatised in 1994, Richard Budge formed RJB Mining and bought most of the pits in the UK , including Gedling Colliery site, with the intention of extracting coal from the tips to sell to power stations. This coal was called slack and was small coal around 1 inch round. Coal naturally has a water content of 40-50%, but over time this increases when deposited in the tips/slag heaps. Once the water content is more than 75% the coal doesn’t meet quality standards and the power stations wouldn’t buy it so the enterprise never took off. Budge quit as CEO of RJB mining in 2001, and the company became known as UK Coal. UK Coal completed some restoration works on site including extensive tree planting. 2003-2013 – The majority of the site lay dormant without a permanent use, during which time plants and insects began to colonise the site. 2012 – Alkane Energy developed “Gedling Energy Park” – a methane extraction plant on a small part of the site. Methane is a gas formed as part of the process of coal formation and coal mining releases methane from the coal seam and the surrounding disturbed rock. 2013 – Gedling Borough Council acquired a 25 year lease from the site owners Harworth Estates (partially owned by UK Coal) to develop Gedling Country Park. This lease excluded the land which has since been developed into a solar farm by Anesco who has a separate lease with Harworth Estates. 2014-2015 – Gedling Borough Council undertook remediation works to make the site safe for the public. The works started in March 2014 and there were several stages of development. To date, this has involved removing the remaining mining infrastructure, laying and covering an extensive network of drains on site, fencing, laying footpaths, installation of park benches and bins, and construction of the top car park and access road from Spring Lane. Future developments will include a children’s play area and visitor centre. 2015 – On 28 March 2015, Gedling Country Park officially opened to the community. 2016 - The park is awarded the Green Flag Award and a new children's play area opens, along with toilets. 2017 - A new visitor centre opens containing "Café 1899" - so named to commemorate the opening year of the colliery. Also, a new artwork is unveiled in the Memorial Garden. 2018 - Two new memorial benches are unveiled in the Memorial Garden. |

Gedling Colliery Facts

- In Britain, coal was formed at various times between 170 million to 300 million years ago. Coal began as ancient forests and vegetation, which became buried and compressed by earth, rock and lava over long periods of time. The rotting vegetation was eventually composted and compressed under extreme pressure which formed coal. - At its deepest, the Gedling Colliery mine was over 1,200 feet deep - nine times the height of Gedling's All Hallows Church Spire. - The mine tunnels stretched out 5 miles in either direction. - At the widest, the mine faces were 250 yards wide. - There was 35 miles of roadway below ground. - At its height of productivity, there were more than 3,500 men working there. - After World War II, there were men from over 20 different nations working at Gedling, earning it the names "UN pit" or "the pit of all nations". - 130 people lost their lives at the pit during the 93 years it was open. - Coal was sold from the Top and Bottom Wharfs: The Top Wharf was at the top of the colliery site (now Chartwell Heights) and was the main selling point for domestic sales to local firms Leapers and Trumans. The Bottom Wharf was closer to Gedling village (the old Grey Goose Pub, now Gedling Village Care Home). From here coal was sold directly from the weighbridge. Leapers would deliver coal collected from here to all local miners. - At the start coal was “hand got” - each miner was expected to work a seam nine yards long and five feet deep each day, producing 16 tonnes of coal during an eight hour shift. - As technology developed, the seams were undercut with a “Samson Coal Cutter”, underpinned with nogs of wood. During a shift, the miners would break down the supports and pick away at the fallen coal. - There are a number of different methods used to describe methane recovery from coal. The process used in Gedling is referred to as AMM – Abandoned Mine Methane. This means that the plant recovers trapped methane from the mines after they closed. The plant extracts the methane through a borehole and uses it to power generators on site producing sustainable energy. Gedling Colliery Pictures (In most cases Photographer unknown) |

We have written this timeline to give an overview of the history of what we can now proudly call Gedling Country Park. However, we are very keen to build our records and information about previous land use of the site, from its farming history to Gedling Colliery. If you have any information, documents, maps, photos or indeed memories that you would like to share with us please get in touch.

We would like to thank one of our Trustees, Graham Tavner for sharing his knowledge and memories from his 35 year career as an Electrical Engineer in Gedling Colliery. Graham has also supplied some photos of the colliery, which you can view in our Gallery under the ABOUT THE PARK section..

We would like to thank one of our Trustees, Graham Tavner for sharing his knowledge and memories from his 35 year career as an Electrical Engineer in Gedling Colliery. Graham has also supplied some photos of the colliery, which you can view in our Gallery under the ABOUT THE PARK section..

Please see our Park History page for more information on how the country park has developed since opening.